Monday, August 26, 2024

Boulle Marquetry

Boulle marquetry or Buhl-work, as it is ofter referred to, is named after the 17th-Century French ebeniste who propagated its use. In simple terms, it is the use of two contrasting veneers which when cut produce 2 inverted patterns of similar design and size. These materials in the past were most often brass, tortoiseshell, pewter, silver and ebony. Today we find brass and wood veneer popular choices in the creation of new work. It is important to note that all brass marquetry, except for brass inlay, is always classified as Boulle.

The method by which Boulle marquetry is made is elementary in theory, but complex in execution for those with no prior marquetry experience. A prerequisite to the Boulle technique would be the "classical" or pad method and would provide a practicable foundation on which to build. Because of the number of layers and the hardness of said materials, no other method is possible in creating Boulle marquetry.

In the example below 2 contrasting veneers are used - brass and faux ebony. In selecting the veneers it is advisable to have the harder of the two slightly thinner than the other to make the finishing process easier. To begin the materials must first be prepared. Newsprint is glued (hide glue is preferred) to the face side of the ebony. Our intent is to consolidate the veneer during cutting. The brass is readied by scoring the backside with a toothing plane. In the absence of such a tool a paint scraper with a piece of a hacksaw blade attached will suffice. Stroking the brass diagonally in opposite directions will provide a good surface to glue upon.

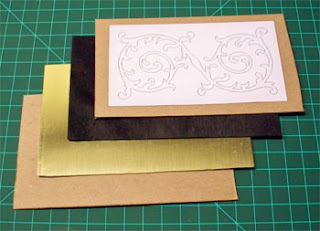

Once the veneers are prepared 2 additional waster veneers are needed. The first for the top to which the pattern will be glued and the second for the bottom to absorb burrs created by the sawblade. It is a good idea to place a sheet of wax paper between the brass and the ebony to help lubricate the blade. Since the brass is more rigid than the veneer it is placed below the ebony. All this is assembled in a pad as shown below. The newsprint is left off in the photo to identify the ebony and the waster veneers are replaced by thin posterboard.

Compact the pad and tape its sides. If a larger pad is made it is advisable to make the pad oversize and glue or pin the edges.Sawing is to be carried out perpendicular to the sawblade. The blade itself should be a metal-cutting blade (jewelers saw blades are just right) with slightly rounded backs with fine teeth. Blade size is a compromise between how easily the blade breaks and the kerf it produces. As a general rule, as applied to hard materials, use a #1 blade for 1/40" or #4 for 1/28" veneers. These have 51 and 38 teeth per inch respectively.

To begin sawing the pad a hole must be drilled so as to thread the blade. This is usually drilled in a corner or where 2 intersecting lines meet. Use the smallest possible drill that will accept the blade. Numbered drill sets in the #61-80 range are perfect. Sawing is carried out with a fretsaw or power scrollsaw as illustrated. It is useful to lubricate the blade frequently with a stick of beeswax to facilitate radial cutting. It is not uncommon, however, to break a blade here and there. That is just the consequence of the material being cut.

When the pad has been cut separate the various layers. Be careful of fragile pieces. The top and bottom wasters can be discarded. What remain are 2 reversed copies of the original pattern. These are then glued face down upon a piece of kraft paper with rubber cement or wide blue painters tape. Make sure the scored brass is on the back side and the papered ebony on the face side. The idea is to hold the pieces together and yet to allow them to be positioned securely to the substrate when in the press. Voids created by the thinner brass will be displayed on the face side. Glue is prepared to match the color of the ebony by mixing a pinch of black, water soluble aniline dye. It is then glued to the substrate on one side and a counter veneer on the other. After the glue has cured it is removed from the press. Using a scraper the newsprint is removed and the ebony cut down level with the brass.

This is an elementary example of what can be achieved with the Boulle method. More advanced designs can be made by expanding on the above and any combination of materials are possible including those not mentioned such as pearl, faux ivory and bone. If it is available in thin veneer-like sheets, it can be used in Boulle marquetry.

Friday, March 8, 2024

The Singular Advantage of Liquid Hide Glue

When comparing liquid hide glue to hot hide glue, as the former is a

derivative from the original, the only advantage is the open time before it

sets up. The time it takes for it to fully cure can take 18-24 hours depending

on the humidity. This can be a disadvantage when glueing veneer because

the veneer has an extended period of time to soak up its moisture and must

be clamped until it has dried which means any squeeze thru will have dried

too. In certain cases it is the only alternative when glueing large surfaces.

There are other cold-set glues that are also available, but this post will deal

with hide glue as an organic adhesive.

Other than the above advantage, it cannot excel in any task that hot hide

glue can. Glue joint strength is not any better. It will not bond to itself

unless heated. For restoration and multifaceted piece work it is too time

consuming and creep resistance is marginal under the wrong

circumstances. In glueing marquetry, if the exterior is not taped up you will

have squeeze out amoung the joints. These will have to be cleaned up after

unclamping. Not a fun chore. That is not to say I do not find it useful in

glueing large surfaces. One product I have found superior to others is

Franklin Liquid Hide Glue. This was the first that appeared on the market.

It comes with an expiration date and I have used it 6 months after it expired

with good results. Do not try that with other cold hide glues that are

available.

In contrast, hot hide glue has a quick tack and good gap filling properties. It

will set in a matter of minutes and requires minimal clamping beyond that

unless you're apprehensive. Any squeeze out can be scraped off after it has

gelled. Has no glue line and the best part is it never gets old. Just heat and

reconstitute with water. I've edge veneered marquetry in a matter of

minutes. I have even added a mitered border around a marquetry picture

using only a straight edge, knife and a 45 degree miter gauge in less than an

hour. Fast and perfect miters. I do not claim to have invented the

technique, but neither have I seen it ever done by anyone other than myself.

And you will not find it in any marquetry book.

Sometimes a task becomes easier by using hot hide glue as in the example

below.

The circular cross banding was inlayed by such a method. First, the oval

border was routed out using a laminate trimmer and a template guide.

Tulipwood was used for the cross banding, but to give the appearance of a

circular curvature only one inch of veneer was inlayed at a time. Working

on one section of the oval while another was setting up with hot glue

allowed me to work in an orderly fashion. The whole process took just over

an hour saving me several days of clamping time.

I have always felt that one should adopt oneself to the medium you are

using. There are many more applications where hot hide glue can be useful.

It makes a fast wood filler. Veneer can be sized and flattened. Can even be

used as a finish. Cabinetmakers and instrument makers use it. I even know

a bookbinder who uses nothing else. All that is needed is a glue pot and a

brush. Most woodworkers are set in their ways. Once they learn a

technique, change is not an option to them. I guess I'm guilty of this

because in all the years of creating marquetry using hide glue not one has

delaminated. Sometimes the old way of your forefathers is the best way and

in my case the only way.

Subscribe to:

Comments (Atom)

Some of the material contained within is protected by the intellectual property rights of the author and represent his view as such.They are presented here for educational purposes. All rights reserved. Copyright © 2003-2024 Marquetry by Ron Bowman